Plastic pollution is a growing environmental problem, with billions of tons of plastic waste generated each year. It is non-biodegradable and takes hundreds of years to be degraded. Plastic is accumulated in landfills and oceans, contaminating soil and water, and endangering wildlife. Traditional methods of plastic disposal, such as incineration and landfilling, can have negative impacts on the environment. They contribute to air and water pollution, and taking up valuable space in landfills. However, a new area of research is offering a promising solution: enzymatic plastic degradation.

A Sustainable Solution: Enzymatic Degradation

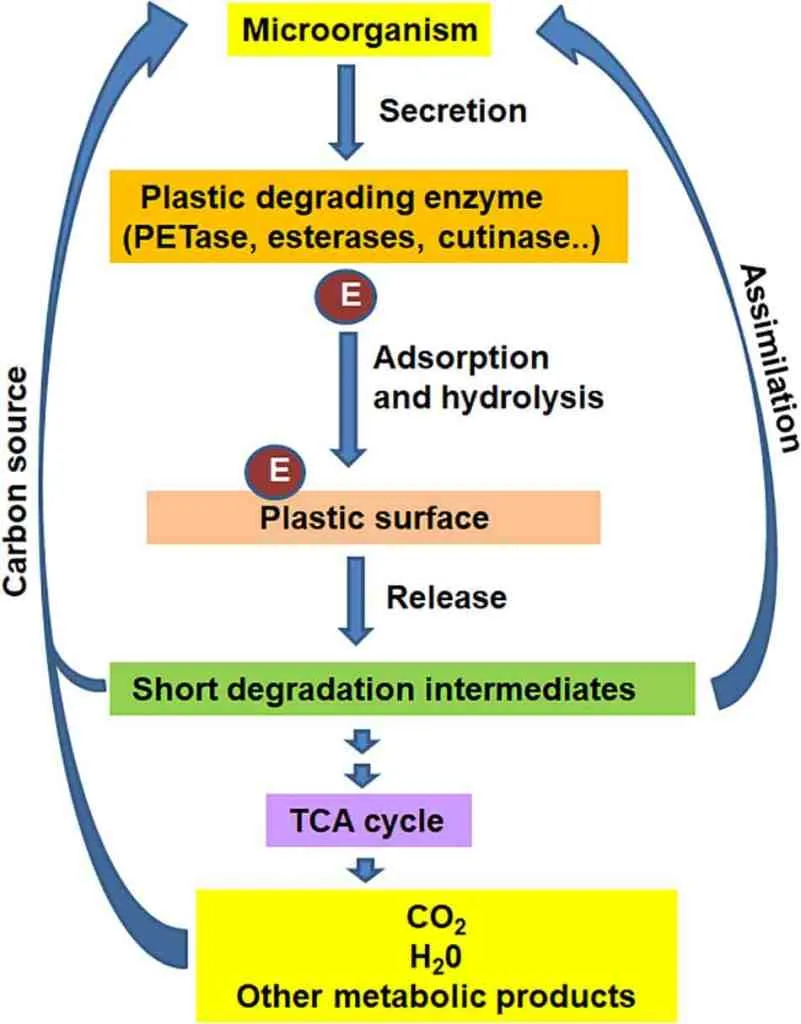

Enzymatic degradation involves using enzymes to break down plastic waste into smaller molecules that can be metabolized by microorganisms. This process is considered more sustainable and environmentally friendly than traditional methods of plastic disposal, as it produces fewer harmful byproducts. Furthermore, it reduces the amount of plastic waste in landfills. Researchers have identified several types of enzymes that can be used for plastic degradation, including lipases, esterases, and proteases.

One particularly promising area of research is the use of enzymes to degrade polyethylene terephthalate (PET). It is a common type of plastic used in water bottles and food containers. Researchers have discovered a bacterium called Ideonella sakaiensis, which produces an enzyme called PETase that can break down PET. This discovery could have significant implications for the future of plastic waste management, as it offers a new, more sustainable way to recycle PET.

Other types of plastics, including polystyrene (PS), polybutylene adipate terephthalate (PBAT), and polyhydroxyalkanoates (PHAs), have also been shown to be susceptible to enzymatic degradation. Researchers are working to optimize enzymes and develop new technologies that can facilitate this process.

The successful development of enzymatic plastic degradation could have significant real-life implications. For example, it could reduce the amount of plastic waste in landfills. That is, freeing up valuable space and reducing environmental impacts. It could also provide a more sustainable and cost-effective way to recycle plastic, reducing the need for new plastic production and the associated environmental impacts.

However, there are also challenges associated with enzymatic plastic degradation. Such as the cost of producing enzymes at a large scale for industrial applications. Researchers are continuing to work on optimizing enzymes and developing new technologies that can facilitate this process.

Conclusion

Enzymatic plastic degradation offers a promising solution to the plastic waste crisis. This technology harnesses the power of enzymes to break down plastic materials into their constituent components, which can then be recycled or safely disposed of. While there are still challenges and limitations to overcome, the results so far are highly promising. Researchers have demonstrated the successful enzymatic degradation of PET and other plastics, and the potential real-life implications are significant.

Enzymatic plastic degradation could transform the way we manage plastic waste, enabling us to reduce our dependence on non-renewable resources and protect the environment. As we continue to explore this technology and develop new methods for enzymatic plastic degradation, we can look forward to a greener, more sustainable future.

Support us to keep independent environmental journalism alive in India.

Keep Reading

What is Green Hydrogen? Could it change energy in South Asia?

Blue hydrogen is worst for climate: study

How Increasing space traffic threatens ozone layer?

Hydro Fuel Market: India’s current scenario and the future ahead

Natural Gas is a Misleading term, It is not Natural and clean at all

Follow Ground Report on X, Instagram and Facebook for environmental and underreported stories from the margins. Give us feedback on our email id greport2018@gmail.com.

Don’t forget to Subscribe to our weekly newsletter, Join our community on WhatsApp, and Follow our YouTube Channel for video stories.